LED selection

In this article, we explain why LED selection is necessary, how it differs between manufacturers and what effects can be expected in practice.

The reason for the selection of LED

The production of LEDs is subject to major fluctuations. This leads to different electrical and photometric characteristic values for each individual LED from a production batch. If the LEDs produced in this way were applied directly to an LED light strip, different and random white tones, colors and brightnesses would be produced over the length. The light strip would not emit homogeneous light. Different light strips that are combined with each other would have visible deviations.

To avoid this, each LED is precisely measured and sorted electrically and photometrically after production. This is called "binning" in English. A "bin" is a container and in practice the LEDs are sorted into different containers after measurement. Each bin represents a group of LEDs with very similar properties. This is the origin of the term "binning".

The selection of LEDs is a decisive quality feature due to the effort involved and has a major influence on production costs. In general, LED light strips with poorer selection are significantly cheaper, although the other technical data such as output and luminous flux are comparable.

The production of LEDs therefore takes place with a considerable surplus so that enough LEDs are available for the planned quantity of LED strips in a "bin".

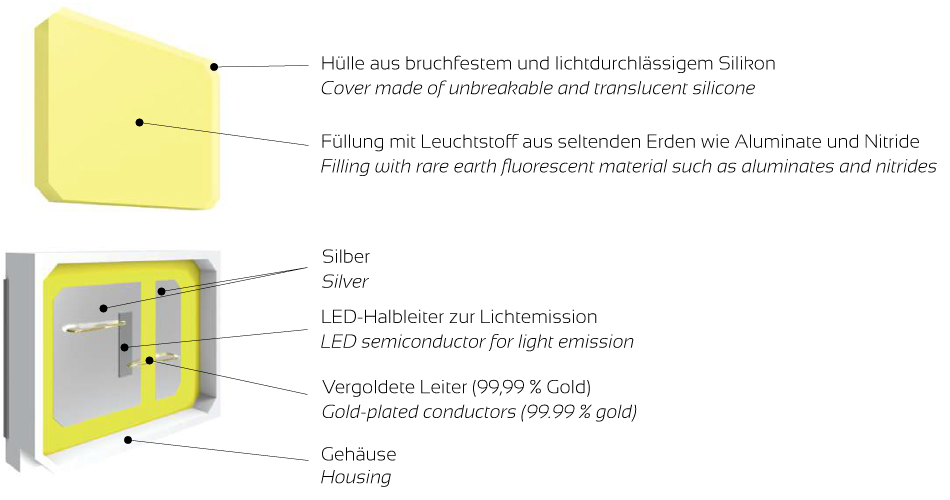

The structure of an LED

The following illustration shows the basic structure of an iluminize LED. We only work with the highest quality materials. The phosphor in the silicone casing is decisive for the selection. The quantity of minerals filled in is very small and difficult to control during production, resulting in deviations. However, it is precisely this phosphor that determines the subsequent properties of the light. It ensures that the blue to green light emitted by the LED is transformed into a natural white tone. The LED illuminates the transmitter from behind.

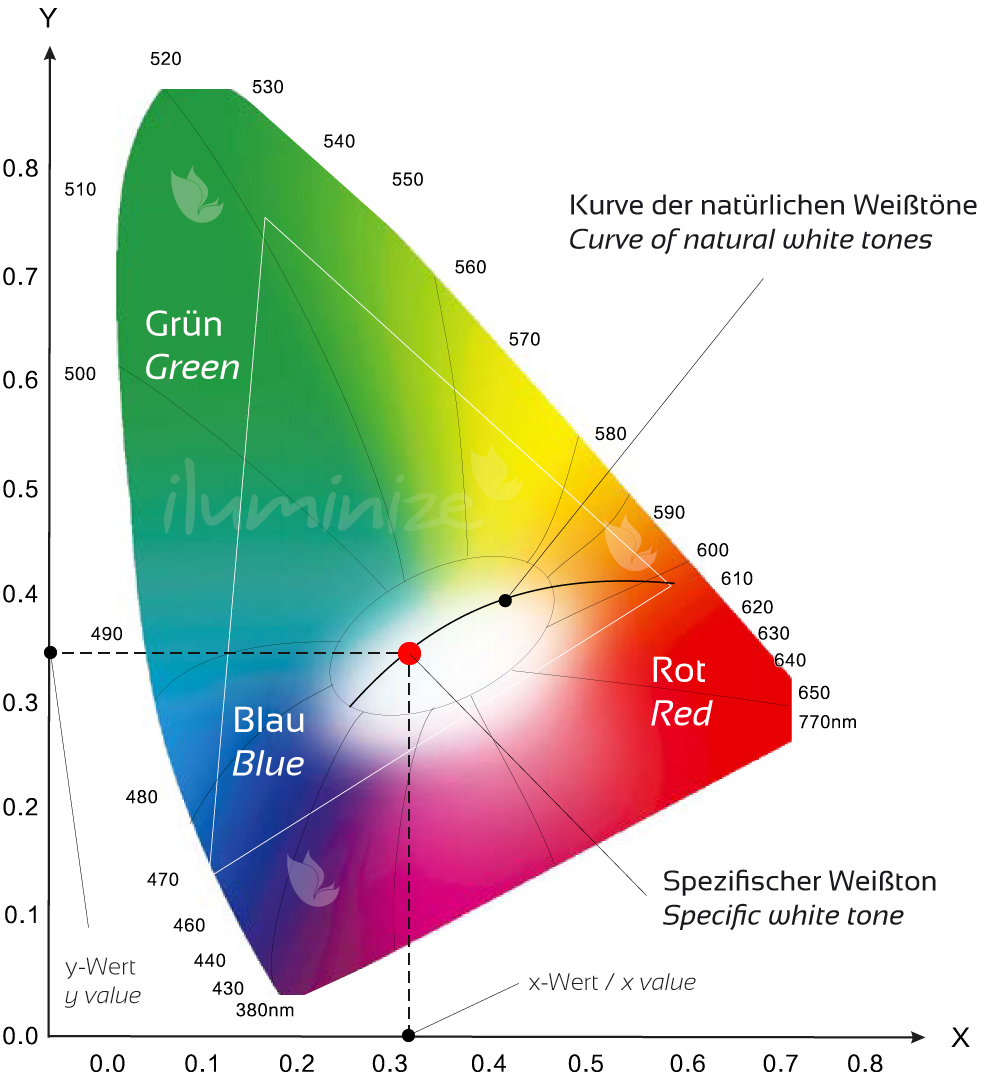

An excursion into the world of colors

Different colors and shades of white can be produced with an LED and by designing the phosphors. The illustration below shows the range of colors and shades of white that can be reproduced with an LED. In addition to the three primary colors red, green and blue, from which the mixed colors can be produced, there is an area in the middle with the white "color tones" also called white tones. The natural white tones are located on the curve drawn in black. The range extends from red - which corresponds to sunset - and blue, which corresponds to daylight.

For better mathematical representation, a color value is given as a combination of x and y values - also known as XY values. This means that each color location is defined by two numbers. For white tones, the tone is also specified in the unit "Kelvin". The white tone marked with the red dot is around 5000 K.

Figure: XY color spectrum for LED

In order for an LED to produce such a white tone of, for example, 6000 K, i.e. a color location defined by x and y (0.31 | 0.34), a special mixture of phosphors must be introduced into the silicone envelope in a precisely defined quantity. If the mixture is not exactly right or the quantity deviates from the specification, the LED emits a different light. This can vary at will and the white tone could be 6000 K or even 4000 K.

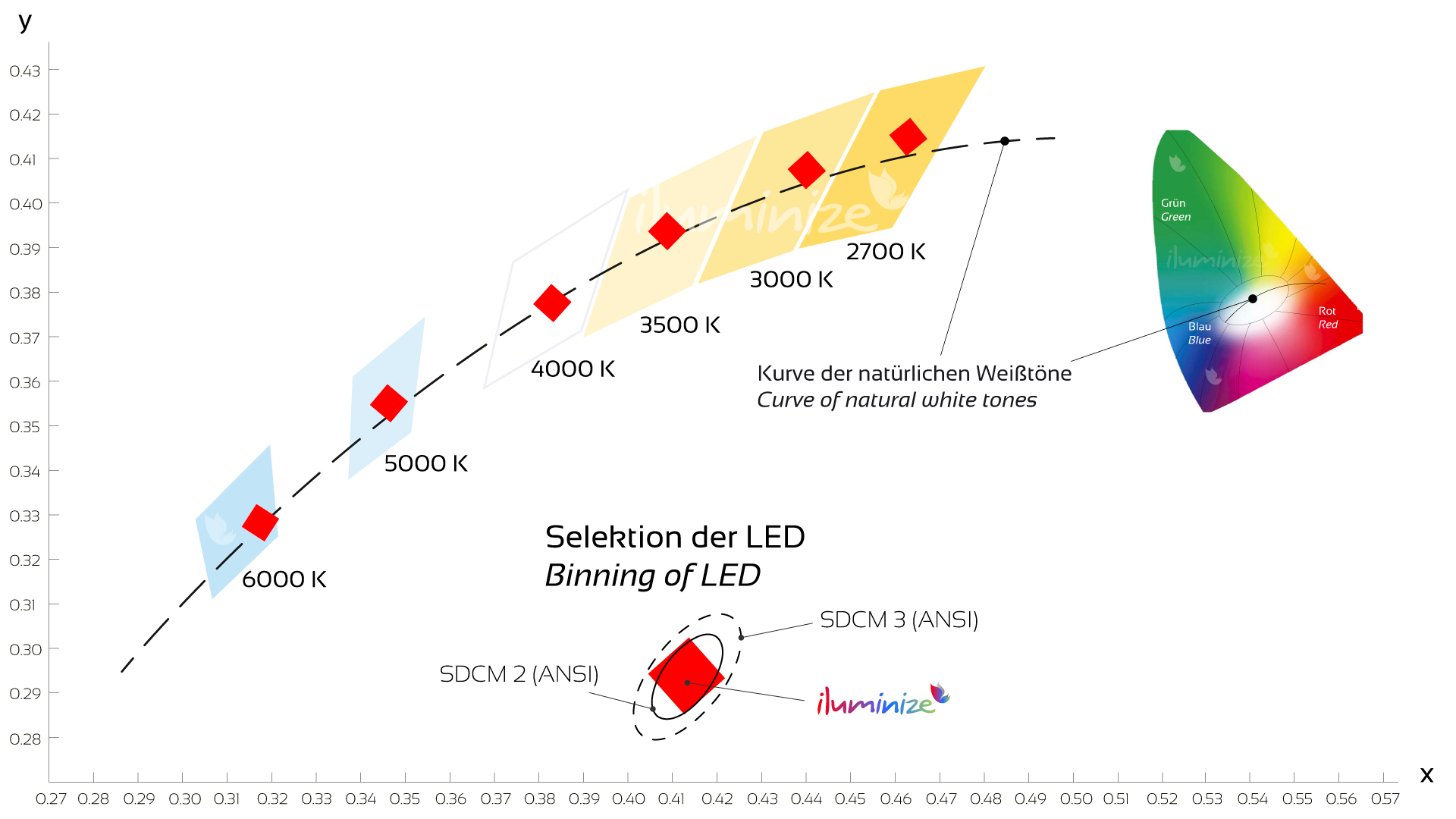

The selection in the color spectrum

The illustration below shows how the known white tones from 2700 K to 6000 K line up along the curve of natural white tones. The areas in which the white tone is labeled the same are the yellowish to bluish diamonds. Each XY value of an LED within the diamonds is (roughly) designated with the same value in Kelvin. Two LED light strips from different manufacturers labeled with 2700 K, for example, can have visibly significant differences in the white tone.

Figure: Selection in color spectrum

McAdam steps or SDCM

Binning is carried out by different manufacturers according to different criteria. The key feature here is the possible deviation from a target value. The diagram above shows the line of natural white tones and the diamonds for the range of a white tone placed on it. For example, if we take the yellowish area at 2700 K, an LED could light up with XY values of any point on this area. The deviation of the white tones is very large. At the bottom left of the diamond, the white tone is already in the range of 3000 K plus red shift, while at the top right it is closer to 2500 K with blue and green shift. The following figure illustrates a strip light with LEDs that scatter within the rhombus of 4000 K. It is clearly visible that some LEDs appear more reddish and others more bluish or greenish. Homogeneous lighting is therefore not possible.

Figure: Scattering of LEDs in a 4000 light strip, SDCM 5-7

In practice, selection methods with elliptical limits have become established. They are known as "McAdam steps" or by the abbreviation SCDM x. The smaller the number x, the better the selection. Only light strips with LEDs that have undergone SDCM 2 selection are suitable for professional use. Only then are there no visible color deviations. Inexpensive light strips are usually made from the LED waste from the production of high-quality products. In the best case, they are then selected according to SDCM 5 or 7 and show a scattering as shown above. LEDs selected according to SDCM 3 are in the mid-price range.

Figure: slight color differences with SDCM 3

Figure: no visible deviations with SDCM 2

The size of the selection area makes the difference

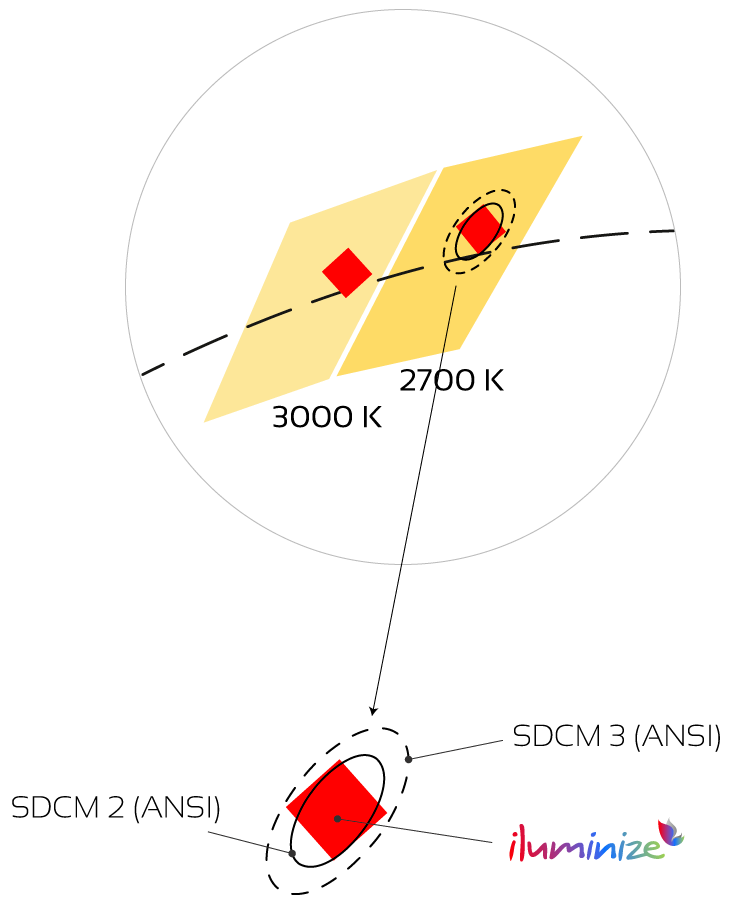

The following illustration shows how in practice a small area is selected from a (rough) white tone - diamond in the graphic. An ellipse is placed around a center point (XY value). The size of the ellipse determines how large the deviation of an LED may be when measuring, so that it is still in the same "bin". The area of SDCM 3 is correspondingly larger than SDCM 2 and therefore color deviations are more likely.

Figure: Selection according to SDCM and how iluminize does it

How iluminize selects

We do not use the ellipses of the SDCM method but use squares. These are shown in red. They are somewhat smaller than the ellipse of SDCM 2 and this type of selection requires more effort. However, it offers the advantage of even more closely spaced white tones.

The same center point is the decisive difference

But we at iluminize go one step further. We always choose exactly the same center point for our selection square, regardless of the batch or model. This ensures that the LED light strips of different models with the same LED type and from different batches cannot be distinguished by eye. For example, if an LED light strip is to be retrofitted in the same place after some time, the white tone or color is the same and no difference is noticeable.

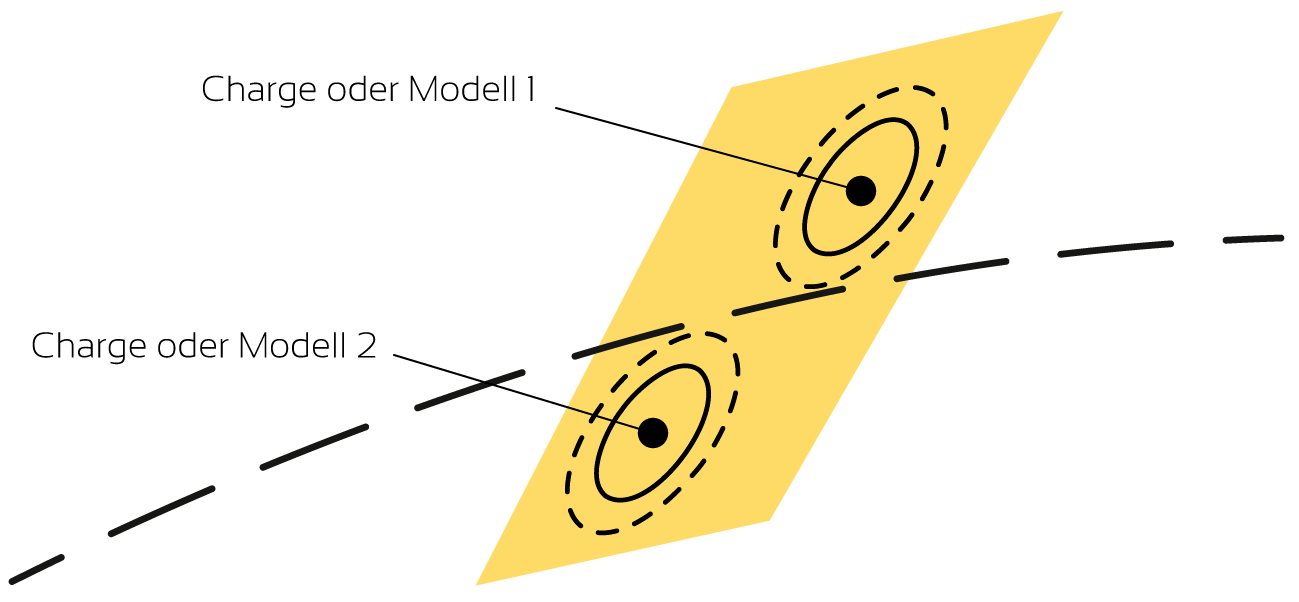

For cost reasons, however, many manufacturers do things differently, as the following diagram shows. A production batch contains LEDs from both SDCM ellipses, which can be used for two different models or batches. If both models/batches are used in one room, differences will be visible.

Figure: as other manufacturers do for cost reasons - different centers

Other influences on the appearance of light

Due to the different designs and sizes of the LED housings, the light emission of the light strips with different LED types differs slightly, despite the same selection of individual LEDs. This is due to the different surface areas and the differing light transmission of the LED housings. A light strip with the 2835 LED will therefore have a slightly different effect than a light strip with the 2216 LED.

The Ra value is also decisive for the mixture of wavelengths of light. Despite the same selection for the same white tone, light strips with different Ra values differ significantly.

The protection class also has an influence on the light. Silicone-coated light strips appear cooler than those without protection. Although the nano-sealing we mainly use offers only slightly less protection against moisture, it only has a very small influence on the light characteristics. The deviation is around 2%. With a silicone coating it is often 8-10%.

Finally, with indirect lighting, the color of the ceiling or wall also has a significant effect on the light emission. The absorption of certain wavelengths can influence the light spectrum and change the effect of the light. For an optimal and harmonious overall impression, the same color should therefore be used everywhere.